Industrial automation equipment plays a crucial role in modern manufacturing processes, helping companies improve efficiency, productivity, and safety. From robotic arms to programmable logic controllers (PLCs), these advanced technologies are used in a wide range of industries to automate tasks that were once performed manually. In this article, we will explore the common applications of industrial automation equipment and how they are transforming the way businesses operate.

Another industry that heavily relies on industrial automation equipment is the food and beverage industry. Automation is used in food processing plants to streamline production processes, ensure consistency in product quality, and meet strict hygiene standards. From sorting and packaging to labeling and palletizing, automation equipment plays a key role in ensuring that food products are safe and meet regulatory requirements.

The pharmaceutical industry is another sector that benefits greatly from industrial automation equipment. Automation is used in drug manufacturing to ensure precise dosing, mixing, and packaging of medications. This not only improves the efficiency of the production process but also reduces the risk of human error, ensuring that medications are safe and effective for patients.

In the electronics industry, automation equipment is used to assemble and test electronic components such as circuit boards and microchips. Robots are used to solder components, inspect for defects, and package finished products. This level of automation allows electronics manufacturers to produce high-quality products at a faster pace, meeting the demands of the rapidly evolving technology market.

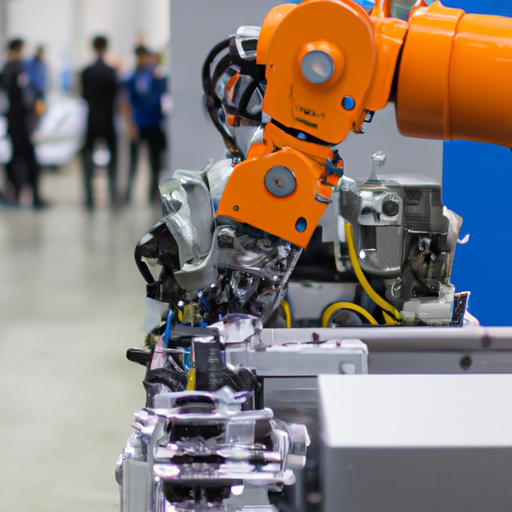

The aerospace industry also relies on industrial automation equipment to manufacture aircraft components and assemble airplanes. Robots are used to drill, rivet, and paint aircraft parts, ensuring precision and consistency in the manufacturing process. Automation has helped aerospace companies reduce production costs, improve product quality, and meet strict safety standards.

In the energy sector, industrial automation equipment is used in power plants to monitor and control the generation and distribution of electricity. PLCs are used to automate processes such as turbine control, voltage regulation, and grid synchronization. This level of automation helps power plants operate more efficiently, reduce downtime, and respond quickly to changes in demand.

The packaging industry is another sector that heavily relies on industrial automation equipment. Automated packaging machines are used to fill, seal, and label products in a variety of industries, from food and beverage to pharmaceuticals and consumer goods. Automation helps companies increase production speeds, reduce packaging waste, and improve overall efficiency in the packaging process.

Overall, industrial automation equipment plays a critical role in a wide range of industries, helping companies improve efficiency, productivity, and safety. From automotive manufacturing to food processing, pharmaceuticals, electronics, aerospace, energy, and packaging, automation technologies are transforming the way businesses operate. As technology continues to advance, we can expect to see even greater integration of automation equipment in industries around the world, driving innovation and growth in the global economy.