PRODUCTS

We provide you with a one-stop service for massive selection

INFORMATION

Overview of information, trends, and policy information in the industry, with a clear view of the world

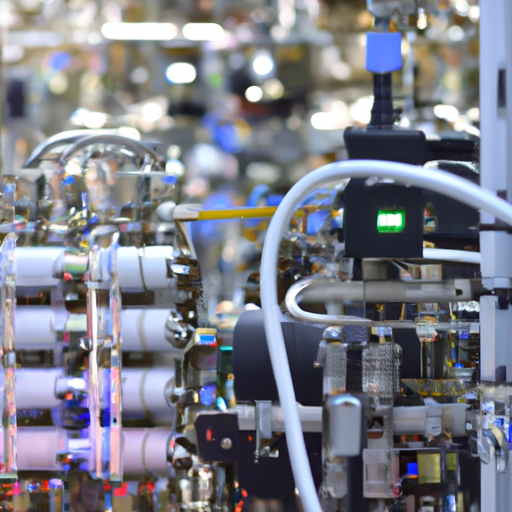

What is the status of the Suzhou Automation Equipment industry?

What are the product standards for Intelligent automation device?

What scenes in life do you use Automated equipment repair

What kinds of common Automated chicken farming equipment

What is the mainstream Maintenance automation equipment production process?

What is the status of the Packaging automation equipment industry?